TOP > Our Business/Japan and Overseas > Production / Manufacturing Sites

At Otsuka Pharmaceutical Factory, everyone in our Manufacturing Division maintains a strong awareness of the part they play in providing medical treatment, and follows GMP documentation and other formalized, rigorous procedures. We recognize that a major factor in determining quality output is how well we can handle increasingly complex, advanced pharmaceutical manufacturing equipment, and software that controls manufacturing equipment, led by computer system validation. Such systems require those involved in manufacturing to have a high degree of knowledge and skills.

Under such conditions, the Manufacturing Division carries out training programs for employees to pass on and acquire correct manufacturing techniques and new skills that we have established over the years. We also provide specialist education to managers, encourage employees to obtain trade skill qualifications, and carry out proposal activities that generate a wide range of creative proposals for improving production. Such efforts contribute to the stable supply of high-quality products.

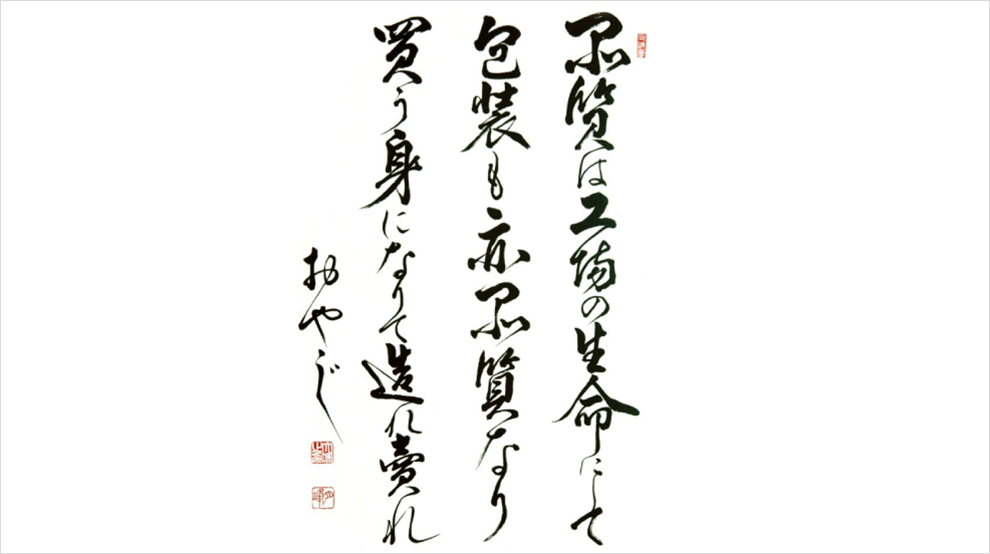

"Quality is vital in a factory and so is packaging. We have to manufacture and market, putting ourselves in the consumer's position. "

This is a saying of the company's founder, Busaburo Otsuka, a man who always insisted that quality comes first. It is an ideal and call to action that has been instilled in all employees since the foundation of the company. They will keep the philosophy in mind and maintain the high level of quality that Otsuka is known for, based on wide-ranging knowledge of the manufacturing process and experience built up over the years.

Otsuka Holdings Co., Ltd. has acquired ISO 22301 certification (the international standard for business continuity management system) to certify that we have systems in place that enable business continuity in emergencies in terms of the production and stable supply of products including IV solutions.

This demonstrates that our system for stable supply of IV solutions meets international standards.

An abundance of clean water is necessary for the steady production of IV solutions.

Our four factories in Japan all manufacture products while living in harmony with a rich natural environment—the two factories in Tokushima Prefecture, one in Naruto where the company was founded and the other in Itano-gun (Matsushige); one in Kushiro, Hokkaido; and one in Imizu, Toyama Prefecture.

Our Head Office and Research Institute are located in the Naruto region, where the Otsuka Group was founded, and the region serves as our home base as a leading manufacturer of IV solutions. Nearby are the famous whirlpools of the Naruto Strait, beneath the Naruto Bridge. The natural environment is also a rich resource for tourism.

The Naruto Factory manufactures injection kit products with transfer needle and plastic bottle products. It also manufactures a brand items with a long history-Oronine H Ointment-and other products.

Received ISO 14001 certification (May 2003)

The Matsushige Factory is located in an industrial park on the Tokushima coast of the Kii Channel, facing Awaji Island and Wakayama Prefecture. It is adjacent to Tokushima Airport and thus has excellent access from outside the prefecture. It is a rationalized and high-efficiency infusion factory, which manufactures 50-mL to 1000-mL single-bag products, double-bag products, and 20-mL plastic injection ampules. It also manufactures double-bag antibiotic kit solutions, which Otsuka was the first in the world to develop.

Received ISO 14001 certification (Aug 2003)

The Kushiro Factory is located not far from Kushiro Shitsugen National Park, a marshland known as a habitat for the Japanese crane. The factory utilizes the features of this broad geographical area with its high-quality water. As Otsuka's production base in northern Japan, the factory manufactures many types of IV products. These include 200-mL to 500-mL single-bag products, 20-mL plastic injection ampules, and four-chamber infusion bags, which Otsuka was the first in the world to develop.

Received ISO 14001 certification (Sep 2002)

The Toyama Factory is situated in a rich natural environment with abundant water. To the north is Toyama Bay and to the southeast is the Tateyama Mountain Range. It is the only factory in Japan to manufacture intravenous fat emulsions.

In addition to 50-mL to 250-mL single-bag products, the factory manufactures double-bag products and four-chamber infusion products.

Received ISO 14001 certification (Apr 1999)